Startseite » Boot washer

Stainless steel boot washer

The boot washer made of robust stainless steel impresses with its versatility for use in agriculture, the construction and wastewater industries as well as by fire departments, THW and other organizations – durable, hygienic and efficient.

Water-bearing hand brushes

for thorough cleaning

of boot shafts

& protective clothing

2 cleaning stations

for boots

Sludge collection bucket with and

without odor trap

Boot brushes with

water spray nozzles

Boot rests with

removable

stainless steel grating

All-round splash guard

- 2 cleaning stations for boots

- Boot rest with removable stainless steel grating

- Brushes with water spray nozzles optimally clean soles and sole edges

- Incl. water-bearing hand brushes for thorough cleaning of boot shafts

- With generous stainless steel base tray for collecting the used water

- Sludge collection bucket with and without odor trap available as an accessory

- Water-bearing stainless steel hand brush available as an accessory

- Incl. side and rear splashbacks

- No power connection necessary

Double

Cleaning stations

Integrated

Stainless steel brushes

Targeted

water supply

Effective

dirt removal

Details at a glance

The boot washer impresses with two cleaning stations and a valve for regulating the water volume, supplemented by splash protection and swivel-mounted water spray bars. Integrated brushes with spray nozzles thoroughly clean soles and shafts, while stainless steel components such as a removable grid and a spacious floor tray make handling easier.

Practical water-bearing hand brushes

Removable grating

Gutter with dirt collection bucket

Technical data

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Housing: Stainless steel

- Grate: Stainless steel

- Dimensions: 1500 mm x 550 mm x 1150 mm (width x depth x height)

- Water inlet: (1 / 2 Cleaning stations): ½” / ¾”

- Water drain: NW50

- Power connection: not necessary

- Weight: 80 kg

Avoidance of contamination and carry-over

How does the black/white separation work?

The black/white separation provides for a spatial separation between the operational and social/civilian areas. In practice, this means that contaminated “black” operational clothing may not be taken into the clean “white” area. This must be separated in accordance with DGUV Information 205-016.

If possible, decontamination should begin at the scene. The contaminated clothing is stowed in a secure container until it is cleaned. The emergency worker is given replacement clothing. Decontamination should be continued on the work site.

The importance of the boot washer

Procedure after contamination

There must be two changing areas in the accommodation. A clean, white area for civilian clothing and a dirty, black area for emergency clothing. In between, a washroom must be provided where emergency personnel can wash before changing from the black to the white area after an operation.

- Boots should be cleaned before entering the accommodation. The best way to do this is in a boot washer.

- The emergency worker then undresses in the black area and leaves their clothes and shoes there. If they are very dirty, they are cleaned.

- Only after cleaning their bodies in the washroom does the emergency worker enter the white area and put on clean clothes and shoes.

Available as accessories

Clean water with every use

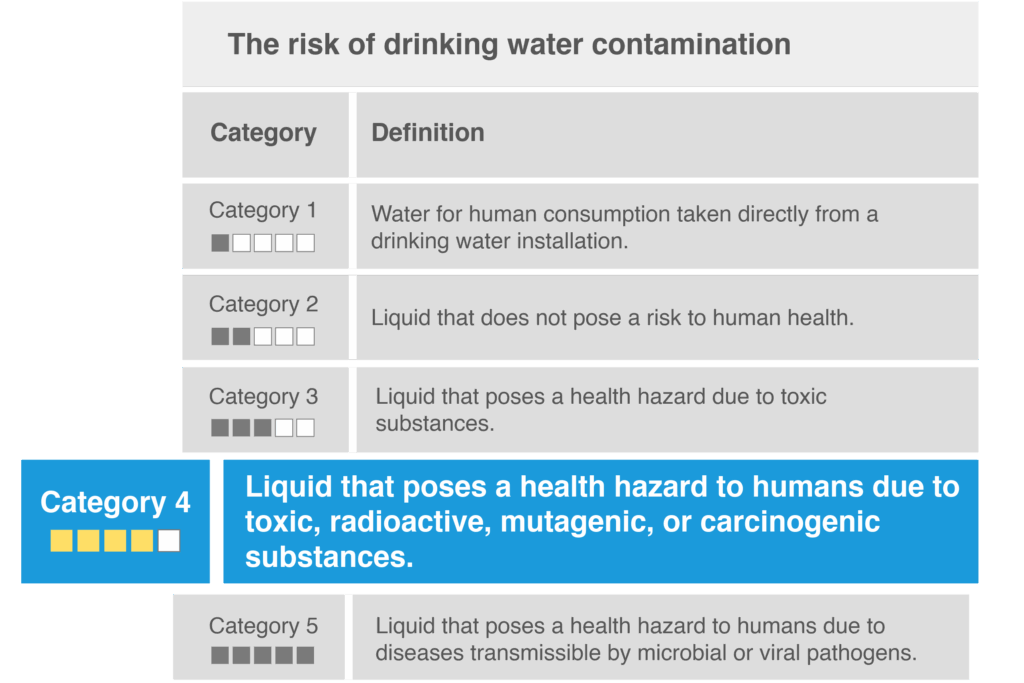

The backflow preventer reliably protects drinking water from contamination – approved up to liquid category 4 in accordance with DIN EN 1717 / DIN 1988-100. This is your solution for ensuring water quality and safety even under demanding operating conditions.

The backflow preventer is equipped with backflow preventers on the inlet and outlet sides and offers hygienic water flow without residue thanks to its dead space-free design.

- Standards & Approvals

- Accessories

The backflow preventer complies with the following standards and approvals:

- DVGW approval

- ÖVGW approval

- SVGW approval up to DN 40

- WRAS approval

- KIWA approval

- BELGAQUA approval

- VA approval

- Plastic components approved according to KTW and W 270 guidelines

- Based on UBA evaluation criteria

- Noise protection approval according to DIN EN ISO 3822 Class 1 up to DN 20 (Class 2 for DN 25 and DN 32)

The following accessories are available for the System Separator BA:

- Soldered union made of red brass, model 476 04

- Female-thread union made of red brass, flat-sealing, model 476 06

- Female-thread union made of red brass with drain, model 476 07

- Male-thread union made of red brass, model 476 08

- Universal union for soldering and pressing, model 476 14

- Press union for Geberit MAPRESS stainless steel and copper systems, model 476 22

- Press union for Viega SANPRESS and PROFIPRESS systems, model 476 30

- Press union for SANHA and NIROSAN systems, model 476 35

- Press union for Geberit MEPLA system, model 476 40

- Press union for Geberit MAPRESS stainless steel system, model 476 20

- Press union for Viega SANPRESS INOX system, model 476 70

- Differential pressure measuring case, model 360 99

Robust materials

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Strainer

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Fuse cartridge

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.